Chain-type multistage weight sorting machine

Multi Tray Weight Sorting Machine

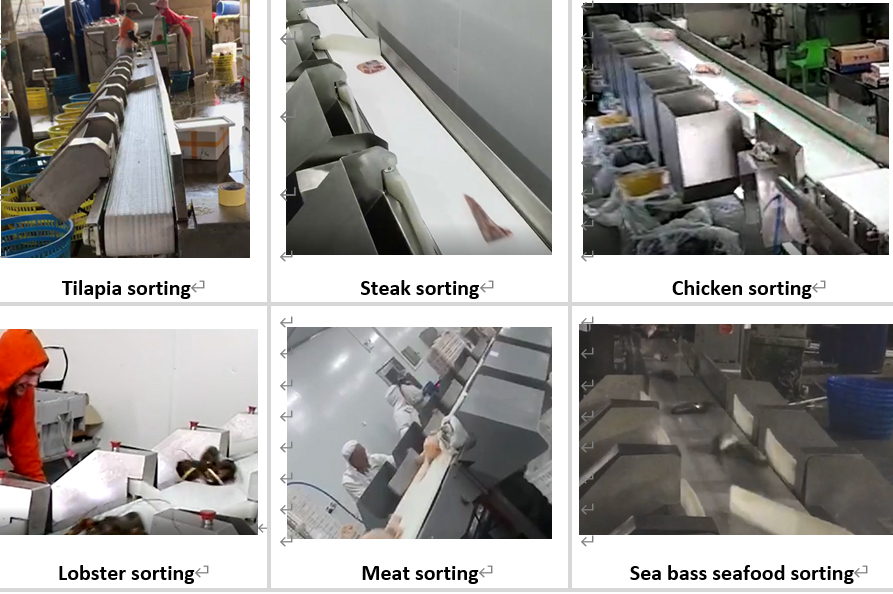

Multistage weight sorting machine is mainly used for automatic quantitative weighing and sorting of seafood, aquatic products, meat and poultry products; That is, according to the target weight set by the product, each product will be weighed separately and automatically sorted to the specified weight grade, providing the standardization of the product, efficiently replacing manual weighing and sorting, and always maintaining product quality and market competitiveness.

The weight sorting machine can screen products of different weight ranges to different production lines, and can fully display production data such as production quantity, batch tracking, total weight, effective weight, and weight after sorting. It can replace manual weighing, help enterprises realize process management and optimize production processes, save financial resources and time for manual operation, and be more accurate. In this way, production efficiency, consistency and reliability of weighing can be improved. While saving labor costs, it greatly improves the standardization of products, bringing more product bargaining space and bargaining power.

Feature

Fully waterproof design, can be directly flushed and cleaned, multiple waterproof protections;

The transmission parts of the electric box bearing are fully sealed

The control part of the electric box adopts a low-voltage safety control design

Food-grade conveyor line that meets food industry standards; quick installation and disassembly, easy to clean and maintain

The whole machine uses S304 stainless steel; corrosion-resistant and not easy to rust;

Professional human-machine interface design

The ten-inch full-color touch screen is clear, bright, and fully intelligent; the humanized button design reduces misoperation

The bilingual Chinese and English tutorial mode is convenient for learning and operation.

Complete software functions

Built-in production records can record the number, weight and ratio of each level in detail, real-time reports, and save data on a USB flash drive

Standard interface, connect to other intelligent communication devices

High-specification configuration

Important components such as sensors, motors, and inverters use first-line brands

Automatic detection of host operation failures and automatic detection of weighing accuracy.

Manual or automatic zeroing, dynamic zero tracking

Use high-density self-lubricating injection molding materials and double contact design to double the wear resistance and service life;

Specification

Model | DKCW5023 | Weighing material size | ≤400mm(L)*200mm(W) |

Power supply | AC220V±10% 50HZ(60HZ) | Weighing table conveyor belt size | 500mm(L)*230mm(W) |

Power | 1KW | Rejection section conveyor | Chain plate type |

Single weighing range | ≤3000g | Elimination method | Swing lever |

Weighing accuracy range | ±1g~±5g | Control System | High-speed A/D sampling controller |

Minimum scale | 1g | Preset product number | 99 |

Conveying speed | 20~80m/min | Operation direction | Facing the machine, left in and right out |

Top speed | 120 pcs/min | External air source | 0.6-1Mpa |

Air pressure interface | Φ8mm | ||

Work Environment | Temperature: 0℃~40℃, humidity: 30%~95% | ||

Machine material | SUS304 | ||

Application case

CATEGORIES

CONTACT US

Contact: Kathy

Phone: +8618122910774

Tel: +8618122910774

Email: 95308765@qq.com

Add: Business Center Rural Commercial Bank Building, Hongfu East Road, Dongcheng, Dongguan city, China